Running high-octane petrol in suitably adapted engine (Concawe Review 29.1)

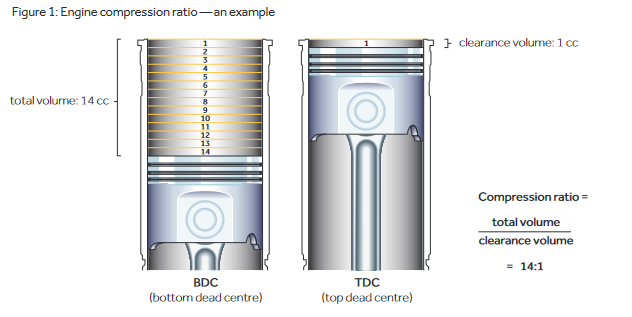

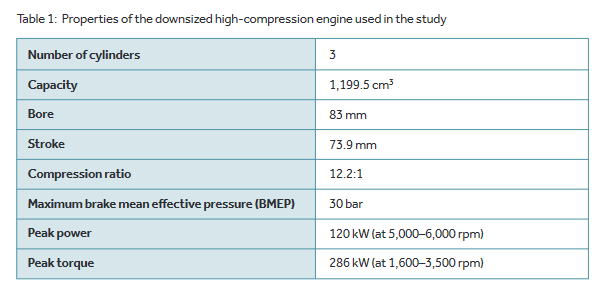

Gasoline combustion has traditionally been measured using Research Octane Number (RON) and Motor Octane Number (MON) which describe the fuel’s resistance to auto-ignition (commonly known as ‘knock’) under different conditions. All modern European gasoline cars must be capable of running on the regular 95 RON grade petrol. However, some vehicles are calibrated to be able to take advantage of higher-octane fuels available in the market, typically by advancing spark timing or increasing boost pressure, which can produce more power and, potentially, better fuel consumption. An article in the last edition of the Concawe Review discussed the possibility of producing higher-octane fuels from a refinery perspective using Concawe’s refinery planning model. The current article is the second in the series, and focuses on a modelling and vehicle testing programme conducted by Concawe to demonstrate improvements in fuel consumption for a range of higher-octane fuels in a specially adapted vehicle beyond the calibration aspects mentioned above. In the future, gasoline engines with higher or variable compression ratios (VCRs) may be made available. While such engines are not commercially available at the present time, the concept is well-understood and demonstration engines exist.  The compression ratio (CR) is a measure of the compression of the air inside a vehicle piston, and is calculated by dividing the total volume of the cylinder when the engine piston is at bottom dead centre (BDC) by the volume when the piston is at the top of the stroke, i.e. at top dead centre (TDC). There are many studies in the literature which suggest that engines with higher compression ratios can take full advantage of improved thermal efficiency when run with higher-octane fuel, leading to improved fuel consumption. The downsized high-compression ratio engine used in this study was used in a previous study [2,3] and was loaned to Concawe for the programme by BP. The engine was a downsized version of a 2.0 litre engine, with a final swept volume of 1.2 litres and a compression ratio of 12.2:1 compared to that of the original engine, which was 10.2:1. The engine details are shown in Table 1 below.

The compression ratio (CR) is a measure of the compression of the air inside a vehicle piston, and is calculated by dividing the total volume of the cylinder when the engine piston is at bottom dead centre (BDC) by the volume when the piston is at the top of the stroke, i.e. at top dead centre (TDC). There are many studies in the literature which suggest that engines with higher compression ratios can take full advantage of improved thermal efficiency when run with higher-octane fuel, leading to improved fuel consumption. The downsized high-compression ratio engine used in this study was used in a previous study [2,3] and was loaned to Concawe for the programme by BP. The engine was a downsized version of a 2.0 litre engine, with a final swept volume of 1.2 litres and a compression ratio of 12.2:1 compared to that of the original engine, which was 10.2:1. The engine details are shown in Table 1 below.  The results of the original BP work showed an improvement in efficiency of ~5% with a 102 RON fuel compared to a 95 RON fuel over a range of test cycles when the two compression ratios were also varied. BP’s work showed that this improvement of ~5% was split into two parts: for example, in real driving conditions, a contribution of 4% was due to the RON increase while a contribution of 1.3% was due to the compression ratio increase. Interestingly, this work also showed that, when the driving conditions are less dynamic (typically the NEDC or WLTC), the RON’s contribution decreases more or less as much as the compression ratio’s contribution increases, so that the efficiency improvement is always ~5% whatever the driving cycle. The current study was carried out to gain a better understanding of the benefits that could be obtained with intermediate octane fuels in between the range that had been studied previously, using the same fuel formulations as those used in the aforementioned refining blending study (Concawe Review, Vol. 28, No. 1), i.e. 95, 98, 100 and 102 RON. A second goal of this study was to further validate these simulation results (based on engine data) with a full vehicle demonstration.

The results of the original BP work showed an improvement in efficiency of ~5% with a 102 RON fuel compared to a 95 RON fuel over a range of test cycles when the two compression ratios were also varied. BP’s work showed that this improvement of ~5% was split into two parts: for example, in real driving conditions, a contribution of 4% was due to the RON increase while a contribution of 1.3% was due to the compression ratio increase. Interestingly, this work also showed that, when the driving conditions are less dynamic (typically the NEDC or WLTC), the RON’s contribution decreases more or less as much as the compression ratio’s contribution increases, so that the efficiency improvement is always ~5% whatever the driving cycle. The current study was carried out to gain a better understanding of the benefits that could be obtained with intermediate octane fuels in between the range that had been studied previously, using the same fuel formulations as those used in the aforementioned refining blending study (Concawe Review, Vol. 28, No. 1), i.e. 95, 98, 100 and 102 RON. A second goal of this study was to further validate these simulation results (based on engine data) with a full vehicle demonstration.